To face of the health and economic emergency connected...

A digital technology for a perfect certified mix design. Up to 15 different formulas and 99 types of materials can be selected with Concrete-Mate.

These elements can be used to obtain multiple combinations to fit any worksite requirement.

When the software has stored a mix design, it indicates to the operator the dosage of each element, the sequence of operations and the working time for each process step, thus avoiding any possible error.

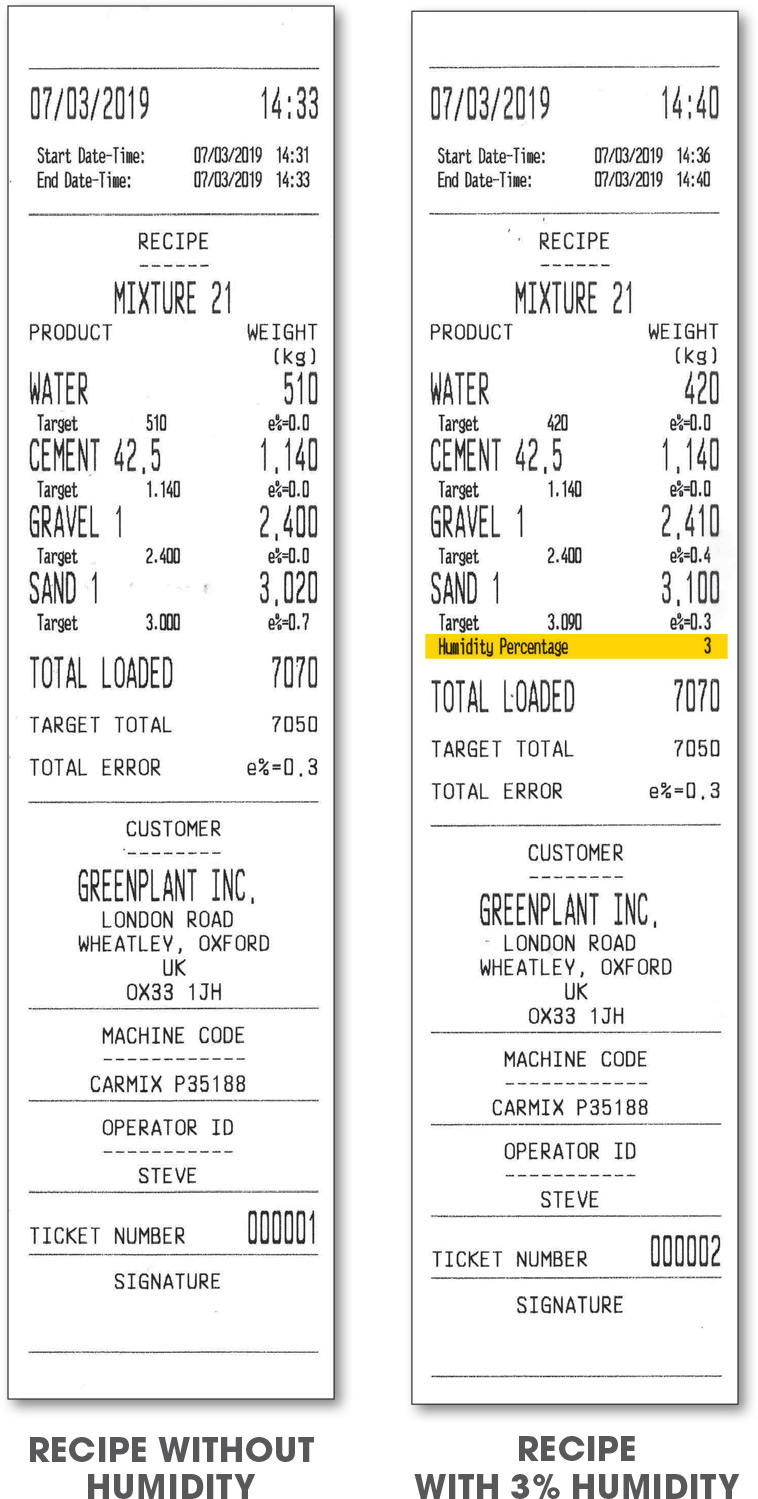

At the end of process the software issues a certificate “RMC PLANT standard” with analytical data of the mix design including the name of Committer, jobsite, operator, mixing time, any weight deviation between executed and recorded mix design by material and by total. Concrete-Mate also works with a software that adjusts the ratio water cement accordingly to the humidity stored.

Management, quality and operating cost control from a remote Internet portal and smartphone app (IPOTweb & IPOTAPP).

The company has developed a web-based control system (IPOTweb) also available on app (IPOTAPP), Working in cloud. Benefits: accurate monitoring of production and product quality and perfect control of operating costs, for a clear, immediate return on investment of CARMIX products.

Monitoring your operators.

Constant upgrades available online.

CONCRETE-MATE CAN ALSO MANAGE HUMIDITY